Industrial Trams – Page 2

An Audience-Participation Layout

Here’s a layout that’s just a meter long and not only provides audience-pleasing operation, but actually makes your viewers part of the scenery! Graffiti Bros. Construction Co. is an urban construction site, served by a small narrow-gauge tram — a typical setup historically and even today.

But there’s a difference in this one! A prominent feature of the scenery is a long wall of 4×8 foot plywood panels. You’ve seen them ringing all urban construction, and usually covered with graffiti. And that’s the “secret weapon” of this layout. It’s a nifty idea that was first floated by Maureen Reddington-Wilde in the Small Layout Design e-group at Yahoo. Here’s how Maureen described her idea:

“Make a traditional scenary block of a long building or fence wall. But make the wall sectional, with slots so each section can easily lift out. Have some fine tipped markers on hand and invite viewers to tag the wall with their own grafitti. A section can be slid out and handed over to someone to add their own art. If all the sections get filled up, new blank ones can be rotated in. This would probably work best with printed card panels. If you print them out on your own computer, you could have a plentiful supply of sections.”

Graffiti Bros. Construction follows Maureen’s idea almost exactly. The plywood fence panels are each removable, and your guests can create their own artwork and have it become part of the layout scene, at least for duration of their visit! The sketch at the left gives you the idea.

Graffiti Bros. Construction follows Maureen’s idea almost exactly. The plywood fence panels are each removable, and your guests can create their own artwork and have it become part of the layout scene, at least for duration of their visit! The sketch at the left gives you the idea.

In Gn15 the 4×8 panels will each be 2″x4″, and in On30 they’ll be 1″x2″ — both plenty large enough to get creative with a marking pen.

Behind the fence wall is a construction site, which can be a building, a bridge, a tunnel, or a monument. The front wall partially hides the traverser (transfer table) as well as a yard for displaying all those great earth-moving vehicles that you couldn’t resist buying but really have no place to display. An exhibition of construction-yellow models waiting to be used solves that problem!

The rest of the layout is a straightforward switching network that provides plenty of scope for shunting games as well as planned arrivals and departures of trains of supplies, equipment, and even workers coming to the job. The track is designed to use standard Peco turnouts, and the walls conveniently separate just at the point where the very-attractive double-slip switch is located. No need to miss any of that fascinating action.

But it’s the thrill of beng involved directly in creating the scene that should bring your guests back again and again to operate and decorate this little layout! Many thanks to Maureen for sharing her idea with us and for giving me permission to design a layout around it.

Notable Norwegian Narrow Gauge

From Norway comes a charming little bit of industrial nostalgia coupled with an unusual shunting puzzle. Jon Songøygard designed the Crow Hill Railroad to represent the present-day remnant of a once much-larger industrial tramway in southern Norway, serving a metallurgical industry complex.

From Norway comes a charming little bit of industrial nostalgia coupled with an unusual shunting puzzle. Jon Songøygard designed the Crow Hill Railroad to represent the present-day remnant of a once much-larger industrial tramway in southern Norway, serving a metallurgical industry complex.

Inspired by an artist’s rendering of the boardwalked main street of Prince Rupert, BC in Canada (at right), Jon envisioned a line founded in the 1860’s by enterprising Baron Friedrich von Rumpelherrn to serve his production site … with an extension up the hill to the baronial mansion and to the deer hunting grounds for the use of guests. When the Norwegian State Railways built a normal (standard) gauge branch line in the 1920’s to serve the site, some of the narrow gauge trackage was removed, including the sight-seeing and hunting line.

But the little railroad has continued until today hauling indispensable goods and materials from Factory A to Loading Dock B, where it interchanges with the normal gauge line. This little layout is designed for a 32″x18″ area in HOn30 or OO9 scales.

Jon sees the line as presently being served by two aging steam locomotives–Emma and Clementine. Emma has a sounder boiler, so is usually the motive power of choice. But alas, Emma also has a tendency to run onto the ground, derailing at awkward moments. A typical such moment is shown in the layout diagram.

The switching dilemma is this–Clementine has taken over the task of shifting the heavy wagonload from A to B, but must make use of the remaining narrow-gauge trackage to do the job. Can you find the easiest route?

The game becomes more complex when the concealed fiddle yard (behind the factory) emits another wagon or two into the traffic stream, and Clementine’s problem is thus compounded as the tail tracks are relatively short–most only hold a locomotive and one or two cars! To further complicate the shunting puzzles, Emma can derail almost anywhere on the layout, causing shunting problems of many different kinds to occur. You’ll have to build the layout and try out various combinations to find the boundary between the merely difficult and the totally impossible!

Some modeling notes: most curves are laid to a 6 or 7 inch radius, but there are one or two spots where the radius is reduced to 4 inches–just to make things more interesting. It’s important to allow enough room for two wagons in the tail tracks without adding too much more, and the turntable must be at least long enough to hold a locomotive and one wagon.

All in all, this litle narrow-gauge tram combining charm, delapidation, and a unique shunting puzzle should keep you busy and happily railroading for many months!

A Home for the Li’l Old Winerunner

Chris Mears, who lives in Charlottetown, Prince Edward Island, Canada, has at least two hobbies: model railroading and winemaking. He combines them in Richmond and Queen, a winery tramway based on an 11×17 inch baseboard (about the equivalent of an A3 sheet). The layout represents the winery end of the tramway, which is designed to haul casks to the offstage cellars for aging.

This tiny On18 / O9 line (1/4 inch scale running on 9mm gauge) has a simple, efficient rolling stock roster: two fireless locomotives (“Making great wine is hard enough without having to worry about exhaust from the engines!” comments Chris); a tiny battery-electric loco for backup; four home-made wine-cask transporter cars (four-axle, depressed center flat cars, providing good weight distribution — “important on narrow gauge,” Chris adds); two low-side gondolas (for ballasting and other maintenance-of-way chores); and one coach (for wine tasters and other visitors).

Chris has also worked out the operating pattern for this stock pretty carefully. He describes it in this way:

“Our crew starts the day by bringing the fully-charged engine from the shed (E) to the turntable (F). An ever-energetic crew-member (volunteer?!) hops down from the foot-plate to align the turntable with the spur leading into the winery itself (A). As the engine can only safely handle one loaded car at a time over the line, we retrieve just this one car. We couple on and tow it back onto the turntable whose capacity, coincidentally, is just one car and the engine.

“We swing the turntable to the outbound loads track (D) and push the loaded car onto that line. Uncoupling and returning to the turntable, we head for the yard line (G). This double-ended siding holds two empty flat cars waiting to be loaded with the next cask for the cellars. We couple onto the first car, and shunt it into the winery building via the turntable.

“For the several decades that the line has been in existence, the crews have bemoaned the lack of a third track in the yard, as it would make the next set of moves much more efficient. But cast switch frogs are expensive, and the money always seems to be needed somewhere else.

“We recouple onto the loaded car on (D) and using the turntable again, add it to the string of cars in (G). Once the brakes are set, the engine runs around that string of cars via (D) and the sector plate (C). Because we can handle only one loaded car at a time, we must now push the loaded car onto the turntable, then retrieve it using the reverse of the above run-around move and the turntable. The result of all these maneuvers: the loco is now at the head end of a one-car departing “train”. We leave the yard via the “main line” (D), headed for the cellars where this new wine will age to perfection. ”

Chris also includes a hidden storage line (B), used to store loaded cars and to represent both the rest of the line, including the wine cellar where all of our loads are bound. The operator manually swaps an empty car for the loaded car on (B) — or simply removes the load from the car, which is then ready to return to the yard. Similarly, loads are placed on the cars waiting on loading track (A).

Other operating goodies that Chris has carefully engineered into this little line include the need to periodically recharge the steam in the fireless locomotives — which can be accomplished only in the engine house track (E). Diabolically, Chris would arrange things so that every so often the crew would be gone a little too long, and the second loco have to be sent up the line to retrieve a dead engine. Other operating “extras” include occasional passenger consists passing through, and marshalling cars for repairs on track (E).

All in all, this is a well-thought-out little plan, with a lot of operating fun built in. There’s just one problem remaining: Chris hasn’t yet figured out how to hide the sector plate with scenery! All suggestions gratefully accepted — I’ll be glad to pass along your thoughts!

From Bread Pans to Bedpans …

In the early years of the Twentieth Century many large, sprawling hospitals had battery-powered tramways running through their corridors to deliver supplies, meals, and patients throughout the building complex and to haul away waste materials. Picture long, well-scrubbed hallways with narrow-gauge rails embedded in the gleaming hardwood floors — and quiet trains of specially-designed wagons moving at a slow walking pace from the kitchens and loadng docks to the wards.

Presenting McGee Memorial Hospital Tramway — as it might have looked in 1910. It’s arranged like a stage set, with a long hospital corridor stretching the full width of the layout between two stage-like wings. We first catch sight of a train — a wagon or two bumping along behind a square, electric “locomotive” (see picture below) — through the conveniently open doors of the kitchen.

We peer through a forest of stainless steel and copper vats, work counters, and storage bins, to watch the little trammer pull round the corner and emerge into the hallway. Then it trundles slowly along the corridor, passing many doors and perhaps some perambulating patients, making stops to load and unload as needed. Train speed never exceeds about three miles per hour — the pace of a slow walk — because the patients using the corridor often have limited abilities to dodge out of the way, and emergency stops can be frequent.

Our train reaches a cross-corridor that is built in “forced perspective” — the scenery gradually shrinks and the rails narrow as they retreat into the distance — so an 8-inch recess appears to be a very long hallway! But there’s enough regular-gauged track in front to hold our locomotive and enable it to turn around on the wye (triangle). It leaves a wagon behind for unloading, picks up the one that was left there by the (imaginary) cross-corridor train, and proceeds slowly back to home base (the Fiddle yard) where it’s turned by hand and readied for the next run.

With this track arrangement, it’s possible to run three trains simultaneously on this little layout — a process that is certain to keep the operators on their toes! As designed, the layout is intended for On30 / O16.5 trains, but virtually any gauge and scale from Z on up could be used. Inspiration for this design came from the artist’s sketch below, which shows a typical tram at Hôpital St Jean-de-Dieu in Montreal about 1905.

Staging a shipyard tramway

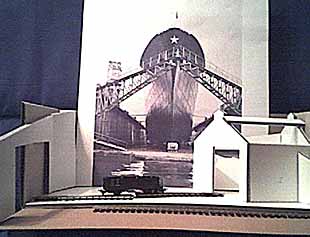

Appearing very much like a stage set is this shipyard tramway, Barbu Wharf, designed by Jon Songøygard from Arendal, Norway. Centerpiece of the layout is a backdrop photo of a giant ship’s prow, along with a tall shipyard crane (the crane’s not shown in Jon’s sketch, below).

Appearing very much like a stage set is this shipyard tramway, Barbu Wharf, designed by Jon Songøygard from Arendal, Norway. Centerpiece of the layout is a backdrop photo of a giant ship’s prow, along with a tall shipyard crane (the crane’s not shown in Jon’s sketch, below).

Framing the dramatic picture and forming the “wings” of the stage are two large industrial buildings–one for production of parts for ship’s equipment, the other for assembly of the parts and installation in the ship. The tramway connects the two.

It’s a narrow gauge road, designed for OO9 / HOn30 scale. There’s a bit of standard-gauge track coming in at the lower left, where raw materials and parts are delivered from the Outside World.

The narrow gauge is a point-to-point layout, moving from the back fiddle yard, through the Production building, across the open yard, to the Assembly building, and around to the hidden fiddle yard again. Although Jon did not specify it, I can’t resist putting in a dotted-line connection that would give a continuous circuit for those times when you want to kick back and just watch a train run round and round!

Jon describes the operations this way: “Traffic mostly goes between the two large buildings. There’ll also be incoming goods from the normal [standard] gauge trains, and some scrap metal deliveries the same way out (the arrows show where I’ll need uncoupling ramps ‘onstage’). After carrying ‘produced stuff” over to Assembly, the wagons will be emptied and the loads may be reused.”

The fiddle yard tracks may be left as simple spurs, as Jon suggests, or could have cassettes attached. The cassettes could be used to replace a train with a different one or could simply be reversed to change the train’s direction.

All in all, Jon has managed a very dramatic stage picture, and a busy operating railroad, in one very small area!

Update: Barbu Shrinks to a Shoebox! (November 2004)

When it came to actually building Barbu Wharf, Jon changed his plans — and redesigned the layout to fit into a shoebox!

When it came to actually building Barbu Wharf, Jon changed his plans — and redesigned the layout to fit into a shoebox!

His idea is to maintain the operating patterns of the original design (except for the continuous loop!), but to make a layout that is easier to carry to train meets and to friends’ houses for visits.

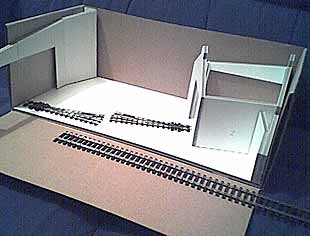

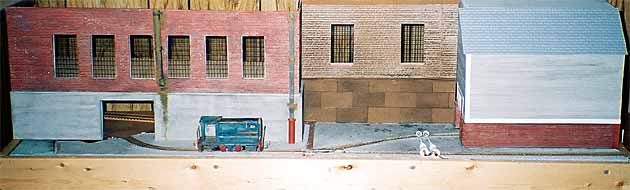

Here are a couple of pictures at the first mock-up, using foamcore walls for background and buildings.

We hope to bring you more pictures as Jon Songøygard progresses! Meantime, you can see his modeling at his website.

A Tram for ‘Stout’ Fellows!

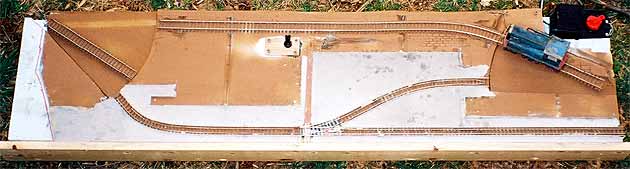

Inspired like Ian Holmes before him by Steve Thomason’s wonderful website, “Industrial Narrow Gauge Railways,” John Glenn from Gastonia, North Carolina has designed and is building this Guinness Brewery Tram. It’s based on the Guinness lline in their home works at St. James’s Gate in Dublin. John is making it in 16.5mm gauge (same as HO), but using 1/32 scale to approximate the original’s 22-inch gauge.

This early construction photo shows John’s progress on trackwork and roads and ground cover (papier maché). With two backstage sector plates to swing, the operator’s job on this little line is going to be strenuous! The railway’s job is to haul raw materials like hops and such into the brewery, then carry kegs of beer out to the interchange to the outside world (lower right).

Buildings are made of foamcore, covered with various “skins” such as Plastruct bricks or Evergreen clapboard siding. The windows were drawn on computer and printed onto acetate. John has a lot of detailing still to do, but he’s capturing wonderfully the spirit of the Guinness line which pops in and out of the brewery’s many buildings in carrying out its duties.

Another of John’s achievements is to have created a scale drawing of the unusual little diesels that served Guinness’s Dublin works. He scaled the drawings from a photo on Thomason’s site: “I used the gentleman standing beside it as a scale reference….First, draw a line from head to toe, assume 5′-8” and project the scale to a line drawing overlaid in Auto-Cad…stretch…pull…assume a great deal, and “ta dah!” you have some resemblence of the real thing! It comes from my surveying days…I’d like input into the actual dimensions to check my fudgilation.”

Another of John’s achievements is to have created a scale drawing of the unusual little diesels that served Guinness’s Dublin works. He scaled the drawings from a photo on Thomason’s site: “I used the gentleman standing beside it as a scale reference….First, draw a line from head to toe, assume 5′-8” and project the scale to a line drawing overlaid in Auto-Cad…stretch…pull…assume a great deal, and “ta dah!” you have some resemblence of the real thing! It comes from my surveying days…I’d like input into the actual dimensions to check my fudgilation.”

John’s model in progress is shown here, made from a converted AHM 0-4-0 chassis.

[ED: Looks like some pretty good fudgilating to me! ]