Single-Level Micro Layouts (Cont’d)

Page 2 of 2

A Pacific Island Sugar Mill

The late Frank Saunders built Pacific Isle, which was exhibited at the narrow-gauge railway competiition at the 2002 Chelmsford Model Railway Club exhibition. It’s a sugarcane hauler built to an unusual scale — 3mm to the foot, on 9mm gauge representing a three-foot gauge prototype.

Operation is simple and prototypical. Incoming trains full of sugarcane arrive from the fields and are unloaded. The cane is then passed by conveyor belt to the crushing area.

Operation is simple and prototypical. Incoming trains full of sugarcane arrive from the fields and are unloaded. The cane is then passed by conveyor belt to the crushing area.

Occasionally, a “Mud Train” of crushed sugar cane is returned to the fields for use as fertilizer. The locos are fueled by the straw left in processing the sugarcane.

Equally important is the excellent sense of locale and “feel” that Frank built into this tiny 20″x30″ layout (50×76 cm). You can almost feel the tropical rain and hear Bloody Mary calling from just down the beach.

Many thanks to Terry Allen for providing photographs and a track plan.

An authentic power plant railway

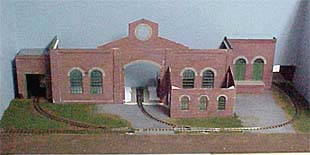

Joe Chiasson, from Ontario, Canada, comes from a power-plant family. His father and grandfather both worked in hand-fueled generating plants, like the one Joe is modelling to be served by a diminutive On15/O9 railway. Joe is currently Chief Engineer of a hospital generating facility of a similar size. Thus, the Frank and Albert Generating Stationcommemorates three generations (pun intended) of station service!

The power plant building, circa 1975, dominates the layout. The railway delivers coal to the boiler room, whose apparent size is doubled by a mirror on the backscene. The coal is simply dumped from side-dumping skips onto the floor beside each boiler, then hand-shoveled into the boilers. Ash is pnuematically conveyed to an overhead bin after it is shovelled out of the boilers front and rear. The way these systems work is that small hatches in the floor are opened and a steam powered ejector sucks the ash from the floor to the bin, from which it’s loaded into railroad cars and hauled away.

A third siding, front left, provides for engine servicing and storage. Notice that Joe has also designed the tracks so they can be operated as a three-road Inglenook switching puzzle, as well as serving the power plant.

This busy little line is based on a similar plant where Joe started working some quarter-century ago (pictured below right) although this plant was not actually rail served. Coal was delivered through the square door to the left and ash departed from the same door. Joe has separated these two functions in his layout, to provide better operating variety. Work has started on the layout (below left), which fittingly will be housed in Joe’s office at a real-life power plant.

For our first layout in April, fittingly presented on April 1st, we have an entry from the most prolific contributor to this Gallery other than myself, Emrys Hopkins.Dapht Woods is a 27″ diameter circle (less than four square feet) with a siding curving to the baseboard edge, so that a cassette can be attached to the layout and stock exchanged.

Minimum radius on Dapht Woods is 5.5 inches, at the start of the anti-clockwise inner sidings (which is cutting it a bit tight, as tippers will have to be pushed into this siding). The road’s operational scheme is somewhat unusual.

As Emrys says, “The intention is that the inner sidings are slightly higher than the outer (clockwise) sidings. I’ve worked out that the inner siding can rise by a quarter inch while the outer one drops half an inch. There’s a tipple to dump goodies from the upper track to the lower track (this might make a bit of a mess, of course).

“The emptied wagon is then taken down to the lower siding and the full one is taken back up to continue the endless circle, so it’s somewhat similar to the

Jaxcilli plan in operation. It’d probably work best in On30, but is feasible in Gn15 as well.”

The B&PRR is a company road that interchanges with a nearby railroad to bring in materials and raw stock and to ship out manufactured products. It’s a self-contained line, with its own switch engines and industrial four-wheeled rolling stock lettered for the company. The little line is primarily designed for narrow gauge — HOn30/OO9, On30/OO16.5, or Gn15 — but with carefully selected rolling stock it can also be built as a standard gauge HO or OO industrial railroad.

Track will need to be handlaid, and you’ll have to scratchbuild a 6-inch diameter turntable, so this is an Intermediate Level layout. Minimum radius is 7 inches, but the ruling radius is 8 inches, and with a little fussing this could be the basic curvature throughout. Needless to say, this plan can be built in a larger space with broader radii, although then it would no longer be classed as a micro layout — but if that approach appeals to you, by all means go to it!

Operations can be hectic and complex — or simple and easy — depending on how you feel. In the complex mode, you can use a removable cassette track to feed arriving cars into the interchange track. If you’re using narrow gauge, you can further complicate the process by requiring a change of trucks (bogies) from standard to narrow gauge at the Interchange point. (The alternative is to assume that cargoes have been offloaded onto narrow-gauge cars somewhere off layout.)

The company switchers can be anything from hard-working Porters in the steam era, to four-wheel diesel critters or even homemade battery-powered locos. To be trendy, you might design the first hybrid-drive industrial locomotive! Whatever its configuration, the company switcher picks up incoming cars at the Interchange and hauls them into the factory.

Your “fiddling around” is done behind the scenes, with a hollow, multi-story factory building shell blocking the audience’s view. You may want to change out some of the arriving cars, place them on the Shipping and Receiving dock tracks (which lead to the turntable), or retain some of them inside the factory building shell and allow the rest to proceed to the turntable.

The turntable is just large enough to hold the switch engine and one car. Arrivals might be assigned one track at the Receiving Dock and be placed there one at a time. You might require them to be spotted in a particular sequence, which could require some sorting using the front end of the passing loop. The switcher could also take advantage of this opportunity to remove the cars at the Shipping Dock track and set them aside for later hauling to the Interchange.

There are dozens of possible variations on this basic operating pattern, and you may want to use a switch list system, or a deck of “event cards” that includes accidents and emergencies to test your switching crew’s mettle. The more cars you have on the layout, the more complex operations become — it’s entirely up to you. Needless to say, the continuous loop provides a place to set up a train and just “let ‘er run” while you watch or socialize — or where you can break in a locomotive. My mail tells me that this feature is highly desirable to a lot of people!

Scrapper Sid’s NG Emporium

By Derek Pratt, our Special Correspondent

By Derek Pratt, our Special Correspondent

Southport, U.K.

This layout represents a small railway scrapyard, where time-expired narrow-gauge rolling stock meets its maker, or rather its undertaker. As we know, most small-scale locos and wagons lie where they fall, slowly dissolving back into the iron ore deposits from which they were formed. However there is a small trade to be had in repairing, refurbishing and recycling such time-expired railway items.

The prime operator in this specialised field is Sidney Smith, alias Sid the Scrapper, a one-time welterweight boxer from the murkier side of East London’s sporting life. Now retired from pugilism, Sid set up his business with the aid of his modest winnings, an out-of-court settlement with his ex-manager and a few dodgy deals with a local councillor. He now happily spends his time with blowtorch and welding set, renovating and repairing what can be salvaged and recycling what cannot.

In reality, this sort of set-up could exist at virtually any narrow-gauge railway, in an out-of-the-way corner of the trackplan where maintenance activity regularly extends the boundaries of the possible.

The layout is a simple oval, with small side branches to hold the stock awaiting their turn for Sid’s piercingly-realistic estimate of their worth. A central area (with gantry crane) is given over to the mechanical side of things, whilst an open-sided shed protects those undergoing more environmentally-sensitive electrical or repainting work.

The far side is used for storage of recovered components and for a loading ramp for road vehicles. Another branch leads off to the main line, if a narrow-gauge development ever had such a thing, so that stock which is merely walking wounded can arrive under its own steam. Repaired items can also depart this way, if not bound for remote parts linked only by road. A small office completes the scene, apart from a myriad of bits and pieces that collectors of railwayana would give good money for. And Sid ensures they do.

The permanent stock consists of a small diesel to act as a shunter and a works train, with a tool wagon, a tipper wagon and a tank wagon of cleaning fluid, for Sid is a stickler for removing the grime obscuring his view of the bare metal. Or as he is wont to say, “Where there’s muck there’s accountants”.

Editor’s Note: This track plan, designed for 16.5mm gauge track with a 6″ minimum radius, was created by Mr. Pratt and later revised and redrawn by Carl Arendt. As shown, the layout is intended for Gn15 or On30/O16.5, although it could easily be converted to 9mm gauge for On18/O9 or HOn30 / OO9. Scenery should be as whimsical as possible, ensuring that the little trains disappear from time to time around or behind giant heaps of inventive scrap.

Circling the Turpentine Still

Paul Boehlert, who lives in Atlanta, Georgia, has crafted a little plant railroad which serves a south Georgia turpentine still. Conceptually, McKamey Bros. Wood Mill is similar to Bott’s Cotton Gin

Paul Boehlert, who lives in Atlanta, Georgia, has crafted a little plant railroad which serves a south Georgia turpentine still. Conceptually, McKamey Bros. Wood Mill is similar to Bott’s Cotton Gin

The plant is entirely self-contained … it saws its own lumber, makes barrels, and renders down the turpentine all at one place. The llittle railroad knits together these parts of the operation, hauling raw materials to each one, and then transferring the completed product to the next stage in the process.

The casks of turpentine are conveyed to the Outside World via the backstage fiddle yard, which is also where new cars and trains enter the layout.

The 6″ diameter turntable, an integral part of the layout’s operations, is adapted from a Peco N-scale turntable, so it should be relatively easy to construct.

This busy little line is a good beginner’s introduction to micro layouts in the smaller scales. It has enough chores and shunting to keep an operator or two busy for hours!

Round and Round They Go!

From England, Keith Addenbrooke has come up with an ultimate in pizza layouts. It’s a double-tracked circuit, capable of running two full trains at one time, in four square feet — and it can be assembled from standard sectional track!

Keith’s basic idea is pretty straightforward. “A pizza baseboard of radius 19.1″ will have a surface area = 1152 sq in (exactly 8 sq. ft or two micros). Cutting a circular hole in the middle to remove half the area will therefore give a four foot square board (hole radius is 13.5″). The resultant ‘ring doughnut’ board is 5.6″ across. It should be the right size to take an inner track of Peco 1st radius curves and an outer track of Peco second radius curves without adjustment.”

He sketched a couple layout concepts using this idea (top two drawings below). The operator sits in a swivel chair in the middle, and the trains circle him or her. This would be an ideal layout to try “plug iin” scenery — which can be swapped in and out — to make several different “looks” with the same track formation. Here are two suggestions from Keith.

At the top is the passenger line. “It has a split scenic treatment,” Keith reports. “It’s half rural with dramatic vertical scenery (and perhaps a viaduct straight from the tunnel mouth) and half urban backdrop.

“The fun comes when trying to switch cars or engines to the far end of the trains (near the road bridge) when the timetable requires the other train to pass through the station at the same time!”

Old time cars (60 feet long or less) are suggested due to the overhang. Spotting a spare car on the Coach Siding (a diner, sleeper or baggage car) allows consists to be swapped around, while using the other siding as a loco layover gives room for a switcher or alternative road engine.

The second layout is mostly for freight traffic. Keith explains, “The inner circuit is used for a ‘loads in, empties out’ operation through the hidden section. “The outer circuit could mimic a railroad interchange at this point. Supplies for the two industries on the inner circuit arrive via the wharf track at the top. Passenger traffic goes round the outer track, stopping at the station (which is shown as rail height platform track with painted buildings on the backdrop).”

As this all seems like a very useful idea, I designed the layout to scale using Roco HO track sections and turnouts (available through Walthers in the U.S.). Everything seemed to fit, although like most micros, it was a tight fit! I’ve named it Foursquare Circles.

The main thing I learned was that the smaller circle (the “hole”) is best cut off-center, to allow room for the sidings at one side of the layout. But there’s no faulting Keith’s arithmetic — the area of the green “donut” is exactly four square feet. It’s a micro layout all right! — Carl Arendt

Here are the track sections required to assemble this layout using Roco track (Peco track would also work and have a very similar parts list): 3x-42464 left curved turnout;

3x-42465 right curved turnout; 13x-42422 R2 (30° R=358mm) curve; 11x-42423 R3 (30° R=419.6mm) curve; 3x-42413 quarter straight.