PAGE 64 – August 2007

H O T I D E A S F O R S M A L L R A I L R O A D S

Back in January, we asked your help to generate ideas about “Hot Topics for 2007”.

Number 1 on the list was Motion Notions (Adding Animation). We wrote:

“One sure fire way to increase the ‘fun content’ of a small or micro layout is to add

animation to the scene.” Apparently many of you agree … the response has been terrific!

So here’s a cornucopia of good ideas you can use on your layout. Thanks to all who contributed!

WIG-WAGS WORK WELL TO WOW WATCHERS

Putting a highly visible animated accessory right up front is a good way to add drama to your small layout. Marcelo Szkatulak, from Toledo, Spain, put a model crossing-guard wig-wag signal at the very front of his HO Espee layout, Patagonia Yard.

The wig-wag is homemade. It pendulums back and forth and makes a loud clanging noise when trains approach the road crossing. Adds considerably to the attention-getting qualities of Marcelo’s line! For more details about the wig-wag operation and construction, see Marcelo’s website.

For a plan and views of the layout, see Scrapbook #36. Marcelo made a short video of the wig-wag in operation, to demonstrate its effectiveness. To see it, just click on the photo below. If it doesn’t appear, you need a WMV Player (free download).

Here is a video Marcelo made showing his wig-wag in operation.

Be sure your sound is on. Click photo below to start video.

(Depending on your connection speed, downloading

may take awhile. Please be patient!)

SOME TIPS ON TIPPING YOUR TIPPERS

The most popular animations are railroad related, particularly when they contribute to the operating fun of a layout. One widely used example is tipping cars and wagons filled with buik materials like gravel, sand, clay, dirt, and so on. Nearly all railways have used open cars to haul such materials — the most popular example is crushed stone for ballast — and modelers have developed a wide variety of methods for dumping those loads before the audience’s eyes, without any “hands on” involvement. Here are some examples that various readers have contributed.

How the Prototype Does it.

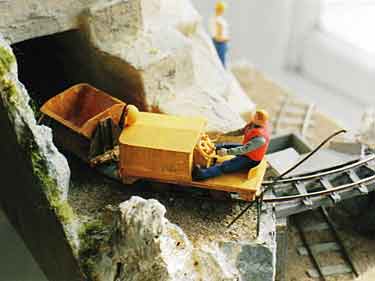

Reader Johan De Groote sent in these photos that he took of a model at the Mine and Mining Museum at Rammelsberg, Germany. Illustrating a method for automatically tipping mine cars, these models are very accurate depictions of a prototype method used in many parts of the world.

A protruding wheel (or sometimes a bar or cone) attached to the car body rides up a trackside ramp, causing the body to tip and discharge its contents. The clever hinging of the side door helps open the side to release the load. Horizontal rods or wheels are attached to the frame, and ride beneath a horizontal bar on the ramp, to stabilize the wagon and prevent it from falling over. One ingenious detail is visible in the righthand photo (above): small ridges are built up on the surface of the ramp. As the tipping wheel bumps over them, they joggle the car to dislodge any stuck particles of the load!

These kinds of tipping cars are sometimes called “Granby cars” and have been widely used over the years in many parts of the world. They make fascinating models! For a considerably less sophisticated example, see the tipping arrangement on my Squarefoot Estate Railway.

For more information on prototypical tipping methods, see “Handling Bulk Materials,” one page of a monumental site about British prototype railway goods (freight) operations written for modelers by a determinedly anonymous author named “Mike.” If he will make contact, I’ll gladly provide proper accreditation (it’s an excellent, non-commercial site).

Some Wired Tipping Methods

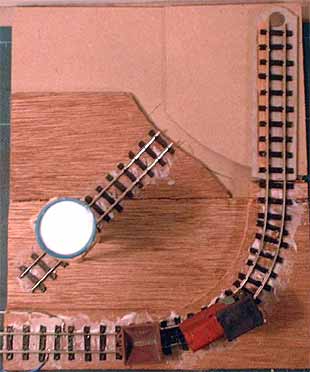

Similar in concept but different in construction is the tipping system that replaces the trackside ramp with a hidden diagonal wire. The idea is well illustrated by Chris O’Donoghue’s Quadrant 1926, an OO9 (HOn30) switching layout in a space of 19x26cm (7½x10¼in). As the pictures above show, a “finger” attached to the hopper of the tip wagon catches on a rising diagonal wire and tips as the car is pushed along the track. Several commercial tipping products use this method, which can be very effective. Needless to say, the wagon frames must be made very heavy!

Chris’s layout was featured in Scrapbooks #21 and #22. It’s shown at right in a more finished form, though many details are still to be added. Notice that the tipping wire is still in place, but has been somewhat disguised by being included in a shed structure. For this photo the wire is painted white so it’s visible; eventually it will be painted black and will virtually disappear. Chris lives near Rye, in East Sussex, England.

Giles Barnabe, who lives in London, England, decided to build a mine-to-tipple layout as a non-competing entry in this year’s Wealdon Railway Group’s competition: “build a layout in a pizza box” (defined as a 12in/30cm square). Giles built it in Gn15 scale (1:22.5 on 16.5mm track). He used a toy Gnomy V-skip, adding a projecting arm at one end. The photos above show the wire armature (actually a thin brass tube) that catches the bucket arm and tips the cargo into an open wagon (gondola) below.

Construction of the layout is illustrated below. Giles built the quarry from a series of boxes roughly formed from scrap cardboard and covered with newspaper soaked in a dilute plaster mix. After drying, the rocky surfaces were created by adding repeated layers of very dilute coloring. The layout is pictured and described in more detail in the current (July/August 2007) issue of Model Trains International magazine (issue no. 71).

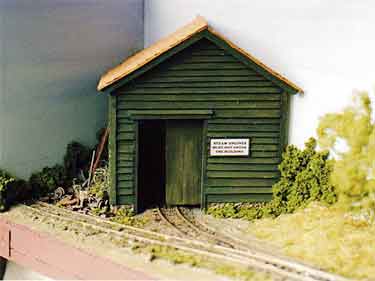

OPEN WIDE, SESAME!

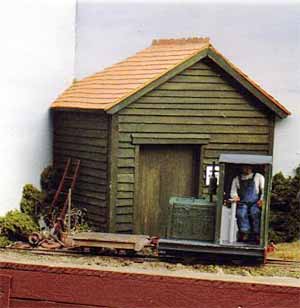

Another animation that wows ’em every time is a door or gate that opens and closes as needed, seemingly without operator assistance. A good example is the door on this shed at the left end of Giles Barnabe’s Futtock’s End Gn15 layout, described in Scrapbook #62. When the tiny narrow-gauge lokeys are ready to push a wogaon or two into the shed, the door slides open (toward the right). When the cars have been deposited and the loco withdraws, the door slides shut again.

As the photos below show, the mechanism is about as simple as can be. Note the runner parallel to the front wall and an operating wire running from back of door out through the backscene. To open and shut the door, the backstage operator simply pulls or pushes the wire! It’s indistinguishable from magic.

A bit more complex is Marcelo Szkatulak’s automated gate opening and closing. The mechanism is based on a 2006 Model Railroader magazine article. It can also be used for opening and closing swinging doors, such as those to a loco shed. Marcelo made a video tape of this effect, shown below. To see it, just click on the picture.

IDEAS, LINKS, AND VARIOUS MOTION NOTIONS

The largest collection of imaginative animations I’ve seen in a single small layout is found on a French HO line called Atmosphère tarnaise. It was a hit at Expométrique 2006, the large train show held annually in Paris. Packed into this tiny module are an amazing number of animations, including a turning windmill, a child on a swing, a camper blowing a fire into life and getting lots of smoke (at left), a chambermaid shaking a dusty rug out of an upper story window, a river with fish swimming in it, a rabbit who pops in and out of the underbrush, and (incredibly) a field of sunflowers whose heads swivel to follow the sun! All these and more can be seen as videos from the report at Ptitrain.com, perhaps the liveliest model railroading website in the world. Thanks to Bart Bakker, from Utrecht, Netherlands, who called this one to my attention!

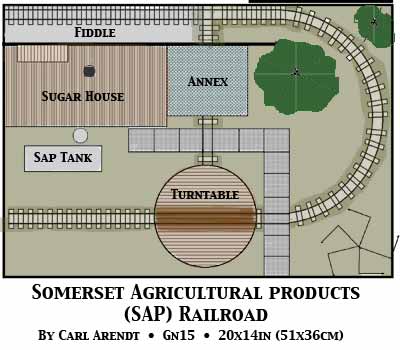

Another use of smoke as a non-mechanical animation device is found on my Gn15 layout, The SAP Line. This little 20x14in (50x36cm) road represents a rural sugar house making maple syrup, surrounded by a cloud of steam.

The effect is produced by a smoke generator in the chimney. It was originally a Seuthe model, later swapped for a larger-capacity Aristo-Craft G-scale unit with a built-in fan. Full story is here.

A potpourri of ideas came from Jack Trollope, who lives in the Highlands of Scotland. Better known by his Internet handle of Shortliner, Jack’s suggestions included the following:

“Do you remember the compressors and jack-hammers that were used to dig holes in streets and made a dreadful row? A man holding one of those hammers — with the drill-point extending through the baseboard to the top of a sub-mini relay, with contacts that power till broken, then spring back to make again — might work well as a little animation, with the road-man ‘shaken’ by the jack-hammer!”

Slowly revolving waterwheels at a trackside mill can be very appealing. See Alex Lehmann’s Rittig’s Mill for one example, shown in Scrapbooks #57a and 59a.

Back and forth motions, easy to create with a crank mechanism, have a lot of possibilities for animation — a fisherman jerking his pole up and down; a carpenter hammering a nail (repeatedly); a gardener hoeing his plot; or a child swinging back and forth on an old tire suspended from a tree. Similarly, heads popping out of windows are sure-fire crowd pleasers. Perhaps a boy leaning out of the window of a tree house for a look around, then retreating back inside … or for variety, a horse’s head appearing from the stable door.

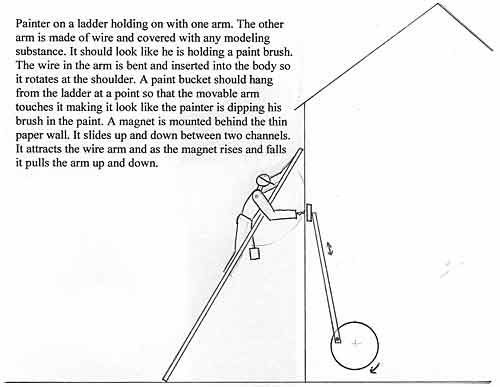

While doodling ideas for micro layouts one day (also one of my favorite pastimes), Jon Winder, from Jenkintown, PA USA, happened to think of this “different” approach to constructing an animated painter on the layout. Jon drew a quick sketch, attached an explanation, and e-mailed it to me.

As most up and down motions are obtained by mechanizing one of the arms of the animated figure, I thought this idea might be of interest as a variation on the theme. Has anyone used the “magnetic” method of animating a figure’s arm?

An interesting idea for industrial animation was added by Garth Groff, from Virginia USA. “You can occasionally find some incredibly small ‘muffin’ fans at very reasonable prices. I found some in a surplus catalog that were approximately 1x1in (25x25mm) and only about ¼in (6mm) thick. One of these would look absolutely great running at a very low speed (reduced voltage) behind a factory window, perhaps with an appropriate screen or grill.”

Another intriguing possibility for using a small magnet to animate a small layout was suggested by Giles Barnabe:

“Small Boat or Swimming Swan. The water surface is a sheet of plastic, suitably coloured. Pulleys (Meccano or possibly LEGO) are arranged below the water with a sprocket chain running round. Attached to the chain is a vertical wire topped with a magnet that just touches the underside of the sheet plastic. The boat or swan is also fitted with a magnet. Only one pulley need be motorised, with the one at the other end of the run running freely. In order to vary the route of the magnet one (or more) idler pulleys can be positioned on vertical axles set in slots so that a spring or rubber band tensions them against the direct line of the sprocket chain, providing a diversion in the route. (Idea adapted from an original thought by Marshall Vine in a vintage copy of Scale Model Trains.)”

Some other thoughts from Giles:

“Animated Animals. Rabbits, dogs, cats (or in a more whimsical setting, dragons or Wile E. Coyote) can be attached to the end of a wire running in a tube, and appear or vanish either manually or with the aid of a slow motion point motor or memory wire.

“Chimney Sweep. Similarly a sweep’s brush can be made to pop out of a chimney, with the addition of an angle crank below the baseboard. Use cranks and equipment intended for model aircraft controls.

| “Hot air balloon ride. Faller make a kit for a hot-air balloon which can be made operational. There are two possible ways of making the balloon fly, depending whether the ceiling over the layout is flat, or is under your house�s roof line, and so slopes. In the latter case a length of curtain-rail is fixed to the ceiling, running up the slope from above where the balloon is to land; ideally there should be at least one foot from the top of the balloon in this position and the curtain-rail, but the longer the better. Attach a thin nylon line from a curtain runner to the top of the balloon, then attach the runner to a winch at the other end of the curtain track. A refinement is to mount an intermittent flasher unit inside the balloon with the bulb just inside the neck above the basket � this can simulate bursts of gas as the balloon takes off.”You need a low-geared motor, a wooden cotton-reel, and a Meccano (or similar) pierced wheel for the basic set up with nylon line between the winch and the runner above the balloon. For the ‘flaming gas’ option the hauling cable has to be a length of very supple miniature twin-flex and you have to arrange to get power to the winch. The lower photo shows one method: two discs of printed circuit board are mounted back-to-back on the end of the cotton reel with wiper arms from phosphor bronze to transfer the power. The cotton reel is screwed to the Meccano wheel which is clamped to the drive shaft of the motor. The ends of the hauling cable (flex) are then soldered to the discs (the outer disc�s wire has to pass through the discs� central pivot hole). A centre-off two way switch is needed to reverse the polarity of the current to the winch motor, allowing up and down motion as well as pause mode. An on/off switch can be fitted to the flasher unit�s power cable, so that the ‘gas’ is only used during flight.”If your ceiling is flat, then just fix the winch in place directly above the balloon’s landing site for a vertical take-off. |

“Flashing. The use of the flasher unit reminds me of its other uses, such as a cutting or welding torch at work. However I’ve also seen it (or something very similar) used to simulate the flashes seen on railways with third rail electrification when the locomotive’s collecting shoe leaves the rail at a turnout, level crossing etc. I’ve seen this effect on a layout depicting the London Underground – very effective!”

For more information on the “how to” part of animation and mechanization in model railways, there are several good books available on the subject from both sides of the Atlantic.

From the U.S., an excellent book is Animated Scale Models Handbook, by Adolph F. Frank. New York: Arco Publishing, Inc., 1981. ISBN 0-668-05118-3. This thorough volume by an experience model railroader covers everything from basic mechanics to special effects of many kinds, including an impressive variety of industrial animations from mines and quarries to meat-packing plants and dairies. Though it’s out of print, you can get this book from Amazon.com or from one of the online used-book services such as aLibris or AbeBooks.

From the U.K., another excellent book is Industrial and Mechanised Modelling, by Dave Rowe. Didcot: Wild Swan Publications Ltd., 1990. ISBN 0-906867-84-3. Dave’s remarkable collection is illustrated with photos and detailed diagrams of his own models, ranging from swing bridges to conveyor belts to real water movement. This one is somewhat pricier than the first, but can be obtained through Amazon.co.uk, from U.K. railway booksellers or from the above two online services.

And also from the U.S., a useful book intended primarily for O gauge three-rail modelers is Animations For Your Layout, by Roy Everett. Nazareth PA: Myron J. Biggar Group Inc., 1999. ISBN 0-9650291-4-X. Roy’s book has lots of good ideas usable in all scales, for animations from amusement parks, cities, countryside, and railroad yards. You can get it from Amazon.com or any of the previously mentioned online services.

PUTTING IT ALL TOGETHER ON A BASEBOARD!

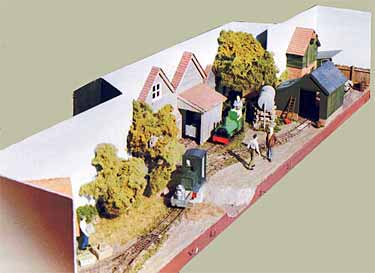

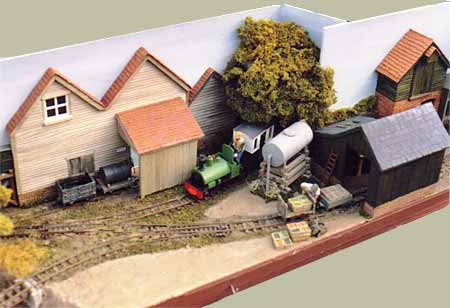

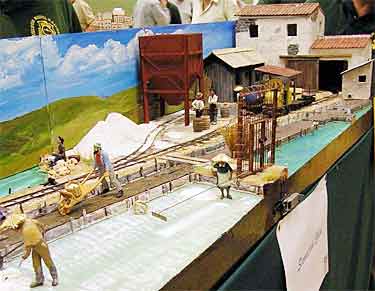

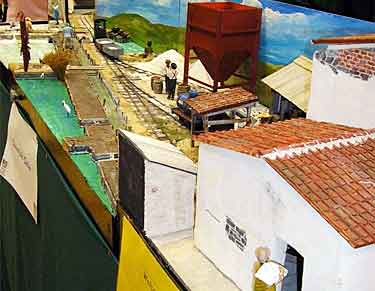

Once you have decided on an animation scene, it’s necessary to install it in a believable way on your layout. Here’s a good example of a layout set in an exotic location, that uses animation in a variety of effective ways and is planning to add even more! It’s a Gn15 shelf layout, Secciole Salina, set in the Eastern Adriatic close by the resort of Piran. Although located in Slovenia the Salt Pan workforce is traditionally Italian and hence the naming of the Layout — Secciole [the name of the area] Salina [Italian for “salt pan”].

Currently measuring 2.2x1m (86x39in), this layout was originally built by Kelvin White, then purchased and is being modified and exhibited by the U.K.’s Basildon MRC, led by Gerry Bullock. It illustrates a typical Slovenian salt site, from the salt flats, to the storage and drying house, to the hoppers that load railroad cars to ship the product. The two overviews above show the flow of traffic up and down the layout.

There are currently four animations, according to Gerry. They are (1) an opening storehouse door to allow train entry; (2) a hopper to load salt (represented by white silica) into wooden railway wagons; (3) outhouse door that opens to reveal the occupant; and (4) an operating wind powered water pump modelled on a Slovenian prototype. The first three are currently hand-powered (manual), while the fourth is electrically driven.

Gerry comments, “There is also a mini diorama within another building where one of the workers is eating a lunch of bread and cheese with a large (very large, it’s 1/12 scale!) bottle of wine on table. This is spotlighted with a diode. Plans are afoot to add a photographer with flash to snap some young ladies sunbathing behind the wind pump in a prohibited area! We will also add a means to load salt into the hopper (a non-operational conveyor).

The hopper and operating storehouse door are shown close up in the photos below. All these animations not only add life to the scene, they also fit right into the railway’s theme and setting, adding local color and charm to a most unusual and interesting layout! For more information and additional photos, see Gerry’s website.

Leave a Reply